A systems post. No fun pictures, no romantic language. You can stop reading here if you don’t care to read about the intricacies of the diesel fuel storage/delivery/polishing system on Horizon. In the broadest sense, this system discussed in this post can be likened to the straw in your drink – you are the engine that wants the drink, the drink glass is the fuel tank, and the straw is the fuel system in between that “just works.” Unless you get a hole in your straw. Or something gets stuck in it. And so on.

The origin of this post is an issue we had when delivering the boat northbound from San Diego, where we bought her, to Alameda where we spent a year working on her. The incident described here led to a rethinking of the whole fuel system, and a first pass at an entirely new setup. There’s probably a second pass coming before too long based on some things that have changed and things we’ve learned. I’ll cover more of that in part 2 if I get around to that.

Horizon has two diesel engines aboard. She’s propelled by a Perkins 6.3544 naturally aspirated mechanically injected straight 6. The hour meter stopped working at ~5200 hours (we keep track of the hours we are adding and someday I’ll fix this). Supposedly there was a rebuild in there somewhere. You can fully rebuild these fairly easily, so maybe it happened. She starts right up, doesn’t smoke, and the oil that I changed about 20 hours ago is still golden. She uses a charming mix of metric and imperial wrenches. And when a solar flare knocks out your modern diesel’s computer right when the zombies are knocking at the door, she’ll probably still be running.

The other is a generator, a Northern Lights 5 kilowatt with a 3 cylinder Lugger engine. We don’t really use it (yet) but if we need AC or to heat up water via our electric water heater we’ll fire it up. In a quiet but crowded anchorage at 5am, as is tradition.

We have two stainless fuel tanks under the cabin sole (floor for normal people) holding about 250 gallons. I say about because – well – I’ve never emptied and then refilled them so I just take this on faith and the listed specs from the manufacturer. Each tank has 2 pickup and one return port(s). For those who are reading this (insomnia?) and don’t know – engines like the ones we have use primary pumps (lift pumps) that bring more fuel to the engine than it needs. This fuel flows to the engine injector system which takes what it needs, and the rest gets sent back to the tank. Hence the return port. The straw analogy falls apart a bit here. It’d be a bit like if you drank from the straw, but a big percentage of the drink passed through your body and directly back into the glass after your body took what it needed. Anyhow, the return port is where this happens.

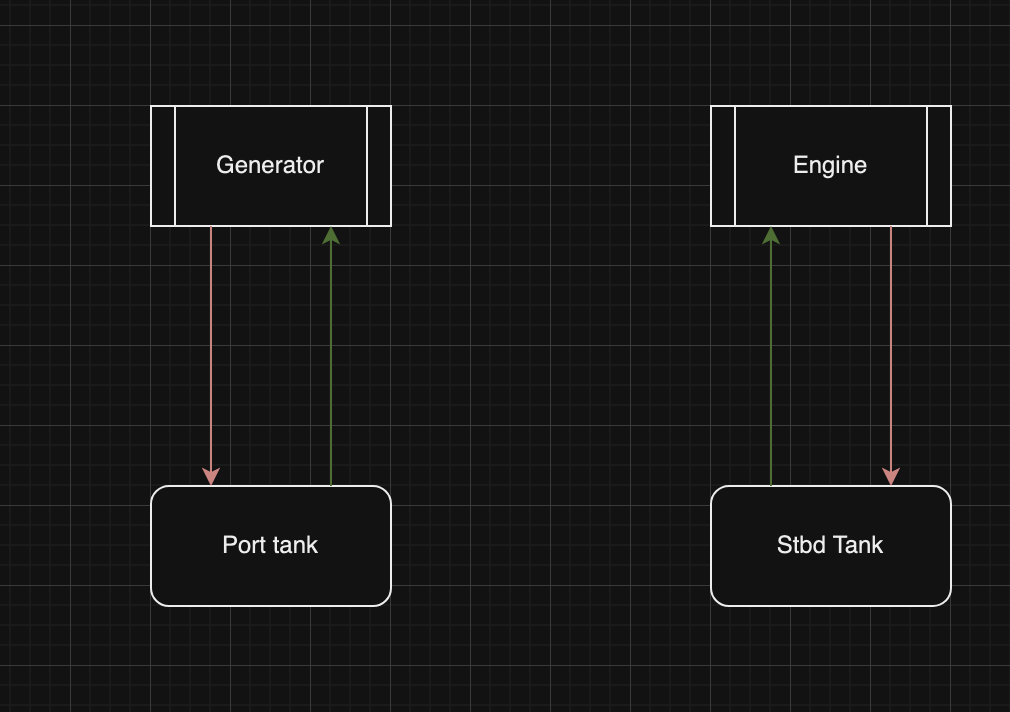

So there are a few ways this could be set up. You could say, for example, that the port tank is for the engine and starboard is for the generator – then you’d just need one pickup and one return on each tank – very simple. Not very flexible.

Normally you want at least your main engine to be able to pull from either tank – say when one tank is empty and you still need to go places. So now things get a bit more complicated. You need to bring two of the pickups together in a tee so that you can pick which tank is providing the fuel. Lots of ways to get this done – on Horizon when we got her it was a tee and two ball valves. So port tank -> valve -> T <-valve <- Starboard tank. From the bottom of the T it’s off to the engine.

Oh and remember the return – this needs the same setup – you want to return to the same tank you’re pulling from, so you need to make sure these are the same under normal circumstances. IE – pick up fuel from starboard, return to starboard. Otherwise you could overfill a full tank, or empty a full tank into an empty one. So it looks more like this:

Note that the generator only pulls from one tank, and is set up to return directly to that tank by teeing into the port return. This prevents you from accidentally using all your propulsion fuel while you watch tv, microwave popcorn, run the AC, dry your hair, etc.

The main engine pulls from whichever tank and returns to whichever (or both, but probably not a good idea to do that for a number of reasons) based on which ball valves are open.

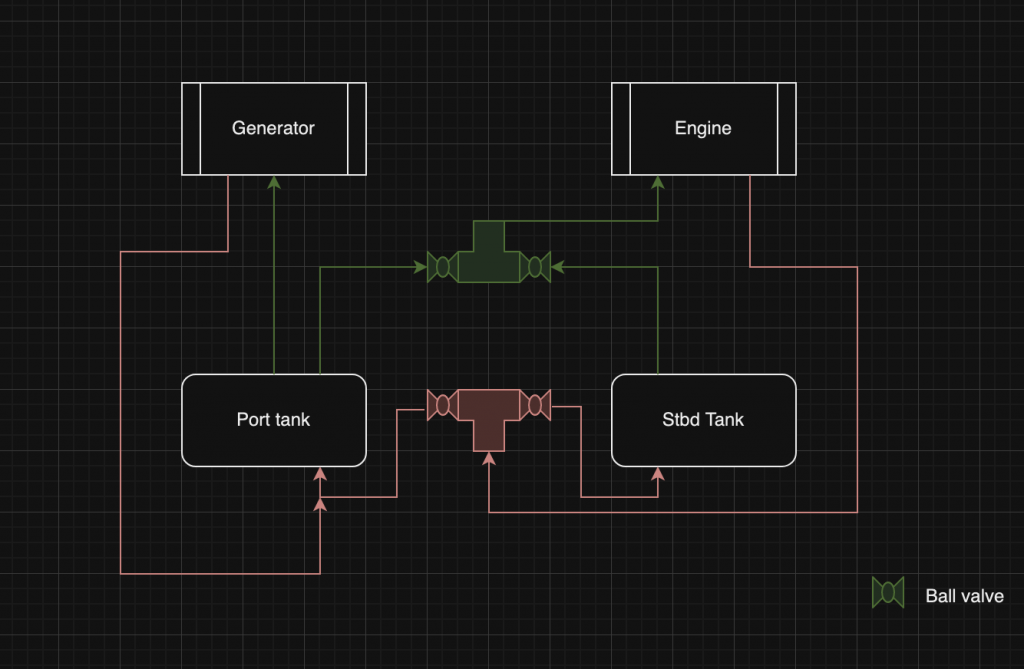

More common (I think), and how we started, is like this:

4 valves to think about (there are cool valves that do this all-in-one but we didn’t have that).

The downsides – you can’t run the generator from a different tank than the main engine, so you have to be much more careful about fuel usage. Not a big deal – just one more thing to think about that you’re probably already thinking about. You also have more connections between each engine and the tank – I didn’t draw them but there’s another pair of tees where the lines come together. One more place that there can be leaks. Also not a huge deal.

The observant reader might ask: “But what about the second pickup? You said each tank had 2 pickups and one return.”

Very good point. In fact, there were fuel hoses plumbed to these pickups. Old copper ones. They disappeared into the bilge and reappeared, capped off, in a little cubby next to the engine compartment. Relics, I assume, of a vestigial fuel polishing system. In our case they weren’t in use.

So that’s how we started. Nothing wrong with the setup above – we had 4 valves to manage, usually open on one side and closed on the other so we used just one tank at a time.

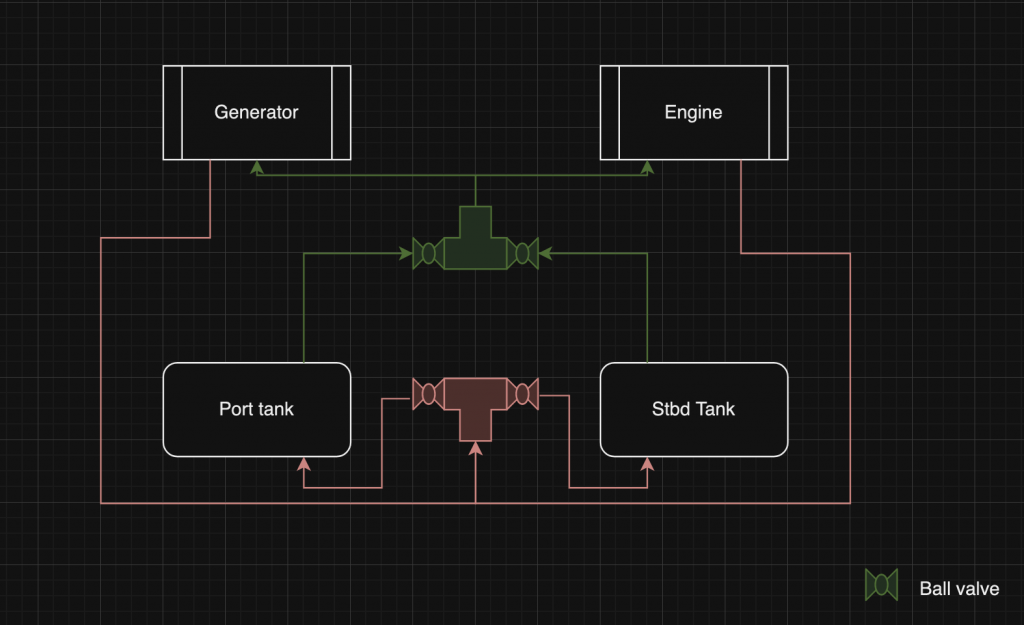

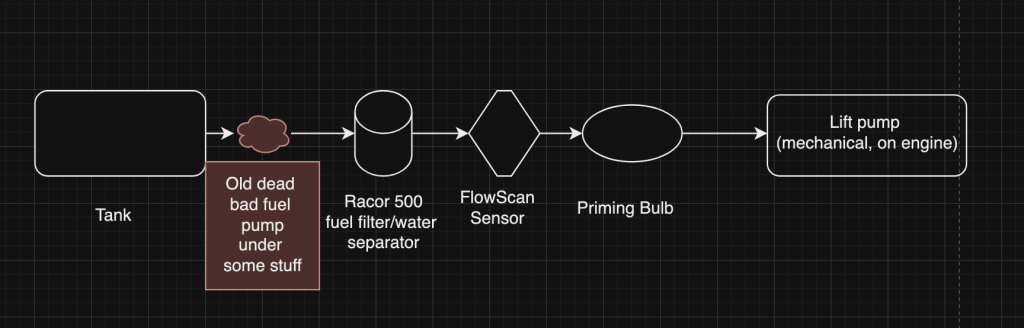

Things got more complicated between the tanks and the main engine. So everything between the big green tee and the engine in the diagram above. Imagine, in the diagram below, that each arrow is actually a rubber hose (but also sometimes some copper hose and threaded connectors and sometimes a bit of both) attached with a hose clamp. So back to the drinking straw analogy, instead of one hose we really have a bunch of hoses clamped together to allow for some additional functions in our straw system. Our straw is much more complicated now, and there are a lot more places where air can get in and break our suction. And this is where we ran into trouble on our northbound trip in May 2023. Here’s what we had, when we left, to my knowledge:

Fairly normal boat stuff aside from the priming bulb, which you don’t normally(?) see here but which is also kinda nice to have. Surveyor said get rid of it, mechanic said keep it.

The Flowscan system wasn’t working – normally this attempts to show how many gallons per hour of fuel you are using at any given moment and tracks this for you so you know how much you’ve consumed. It has a sensor that the fuel flows through and an LCD display that reports the amount of fuel flowing through. Cool stuff. It was on my list to fix (I assumed it wasn’t getting power or the display was dead) or remove, but seemed in fine condition overall.

Racor filters are pretty universal aboard as a fuel pre-filter before the engine that also removes any water from the fuel before it gets to the engine. There’s one downside. Basically – when you change the filter, the fuel drains out and leaves a bunch of air. You remedy this by pouring fuel into the filter housing, usually, and then any leftover air has to be bled from the engine. Some engines can just do this just by cranking them, some need a hand. The Perkins is the latter. Probably why there was a priming bulb installed also – this let you pump fuel from the tank all the way through the filter to the engine and helped make the priming process easier.

The generator was simpler, just a Racor filter assembly inline. It was hard to get to, and to prime it after a filter change was “not fun” and involved pouring fuel into the filter housing, but it was fine.

Anyhow, everything looked reasonably good in March/April 2023: the mechanic made mostly happy noises, the engine ran great, I replaced the filters and bled the engine and changed the oil and then did other things to get us ready for the northbound trip. (The plan, very roughly, was to get the boat to SF, hang out and get our stuff together and the boat fixed up, give Zeppelin a good final however long he had, and then figure out what was next for us.)

For those who don’t know, the wind blows mostly from the Northwest along the CA coast in the summer. Basically from top to bottom. Actually it’s mostly the same in the winter too, except when storms change this as low pressure systems come in from offshore. The wind rotates counterclockwise around low pressure in the northern hemisphere, giving you first a southerly flow that clocks all the way around. Or some variation depending on where the low comes ashore.

The lazy/easy/safe way North is to basically motor when the wind is light (mostly overnight and into the morning), and rest in various anchorages and harbors during the afternoons when it blows hardest. Normally you stay pretty close to shore, within 5-10 miles, to further reduce the wind on the nose. Real sailors probably would disagree, go far offshore, and make the miles upwind. We didn’t do that. Also if you haven’t read Two Years Before the Mast – it’s an interesting account of sailing this coast in the time before engines made it easier.

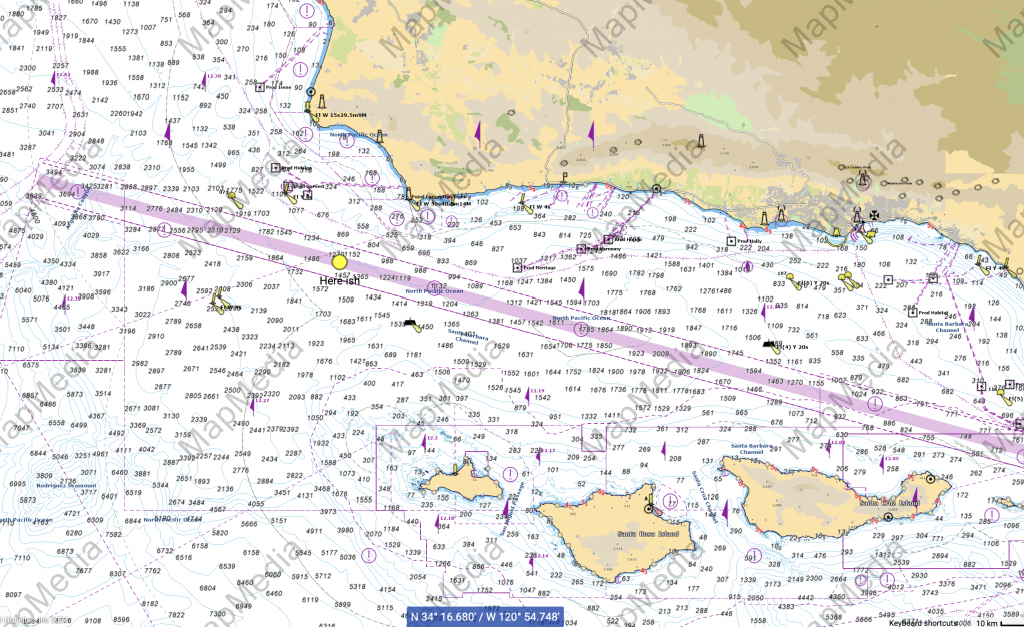

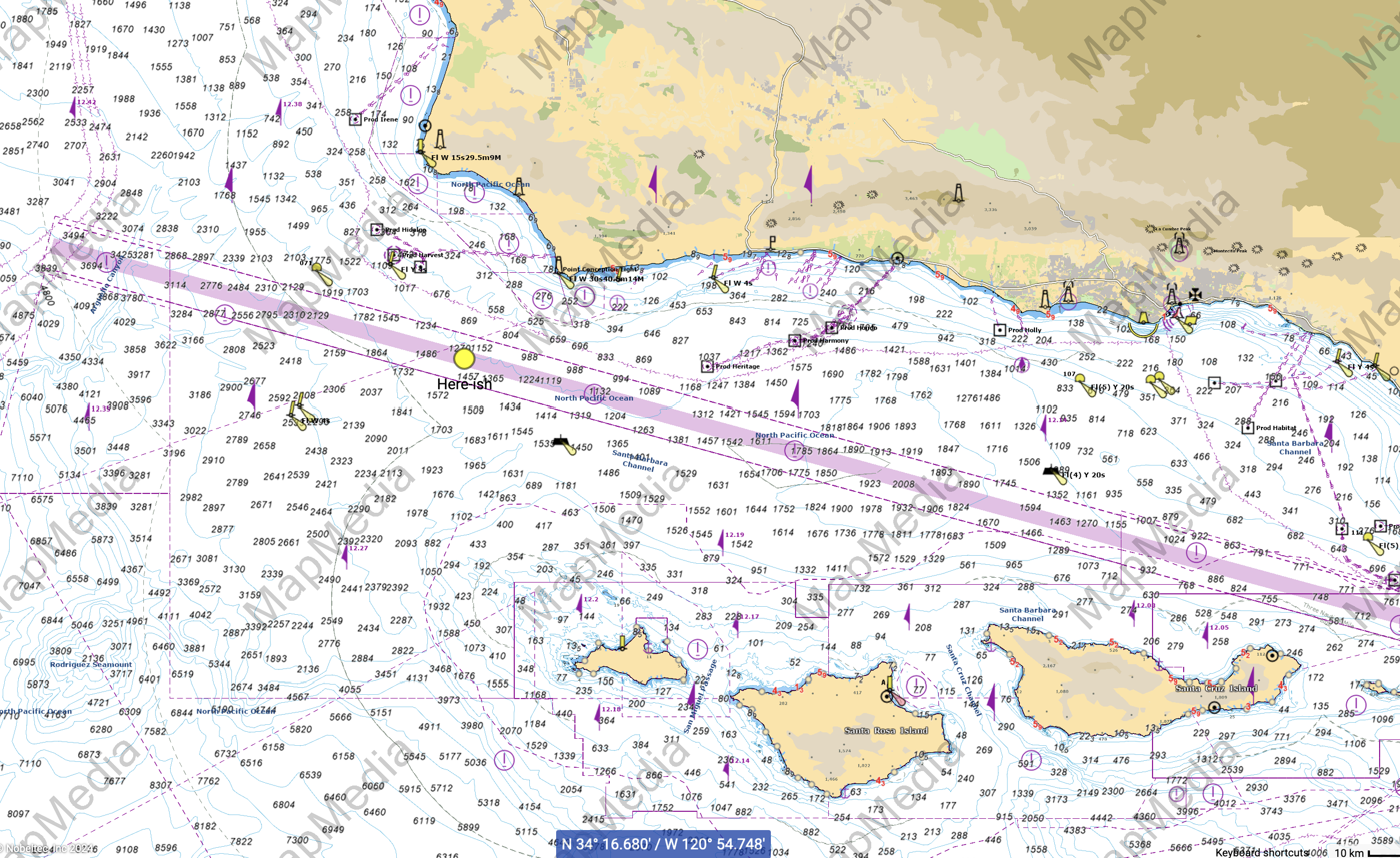

So we set off from San Diego, motoring north and mostly moving overnight. First stop Catalina (left at sunset, arrived just after sunrise), second stop San Miguel Island (left late afternoon, arrived early morning to one of my favorite places on earth). We rested for a few days in San Miguel and then left in the early afternoon. As we motored north from San Miguel Island in the mid-late afternoon on a calm day following a late low pressure system, and just about midway between there and the Point Conception/Point Arguello area on the mainland, the engine sped up (we were running around 1850 RPM, it went up to 2500ish) and then stalled.

We had a few knots of wind, the sun was out, and aside from the confused seas leftover from a storm that had already passed it was a beautiful day. We rolled out the jib and at least moved a knot or two in the right direction. Stephanie steered and watched whales with Stu (my uncle who joined us for the northbound trip and managed to capture a pic of an orca!) while I went to play mechanic. We were in the separation zone of the shipping channel, and I know at least one container ship came by while I was below troubleshooting. There are worse times and places for something like this to happen for sure, but this felt like a less than ideal place to get stuck nonetheless.

So on to the troubleshooting. In general, the symptoms described indicate either being out of fuel, or air in the fuel lines. Or 100 other things. I was pretty sure we had plenty of fuel, and confirmed that first by checking the tanks with their dipsticks. Next – was it getting to the engine? I’d done a trace of the fuel system after we got the boat (everything between the tank selector valves described above and the lift pump that the engine uses to pull fuel from the tank).

Next likely culprit – if the Racor filter gets clogged the engine will be starved of fuel. There’s a gauge on top of the Racor unit that shows when this is happening as you’ll see the vacuum pressure increasing as the filter gets harder and harder to suck fuel through. And indeed, this gauge was in the red. That made sense to me as the likeliest culprit. The boat had been sitting in a marina, and then we went and sloshed all the sediment around the fuel tanks and through the filter, clogging it. Though it didn’t look clogged when I took it out. But I put in a new filter anyway and poured some diesel into the filter housing (this is required, and just as fun as it sounds on a boat at sea). I didn’t think to try and use the priming bulb to fill the Racor, which would have saved a bunch of time troubleshooting as you’ll see.

On priming – when air gets into the system on some engines, the Perkins included, the fuel pump cannot automatically purge the air. And the fuel pump is lubricated by – fuel – so just cranking the engine and praying is ‘bad’. Just how it goes. So if you run out of fuel and/or get air in the system, you have to go through a process to pull fuel from the tanks and through the system, loosening a series of bolts while massaging the mechanical fuel pump on the opposite side of the engine until the fuel comes out and bubbles are gone. This sucks. The priming bulb helps make this a bit easier because it moves a lot more fuel with each pump than the lift pump. So I squeezed the priming bulb now that the Racor was full of fuel and expected to begin pumping fuel to the engine.

It deformed and stayed that way, completely squished. It could not pump fuel. The gauge on the Racor went back into the red. I got worried.

So now the situation is – creating a vacuum on the engine side of the Racor filter yields nothing, just like before the filter changed. So something else at or before the Racor was blocked. Next, assuming we maybe had a clogged fuel pickup (i.e., fuel wasn’t getting out of the tank and the pickup hose was clogged with debris like when you get a seed or something in your straw), I switched the valves to draw from the other tank. Same problem.

This is when I started doing the math on turning towards Santa Barbara/Ventura and when we’d get into range for a tow to safe harbor. Contingencies and all that. I carried some spare fuel line, hose clamps, and assorted fittings, but probably not enough to run a new line from tank to engine, bypassing whatever was clogging the system. I had enough, probably, to go from tank to the Racor. This is also when I learned that the engine had been set up with two different fuel hose sizes 3/4″ and 5/8″. One side of the Racor was different than the other. (This is because there was a hidden length of copper hose under the floorboards and the 5/8 fuel line was clamped onto that. I learned this later, and wish I had noticed this before we left but didn’t.)

I had 3/4″ hose. I had a bit of 5/8″, but not nearly as much. Of course. In any case, I began tracing the route from the supply side on the Racor to the tank in preparation to try and replace that portion, assuming that the old fuel line had collapsed between the tank and the filter. I think we had intermittent cell coverage and this (old fuel lines collapsing) was a thing the internet said could happen. Think of a straw that goes flat when you suck on it.

And in preparing to bypass this section of hose is where I discovered, under some rags and the other spare filters, a small electric fuel pump between the fuel tank and the Racor. It’s not abnormal to add an electric fuel pump to supplement the one on the engine – basically you’re just helping pull fuel from the tanks and send it to the engine, and considering all the stuff the fuel goes through, see above, this is not a bad thing. It also means that your lift pump can fail and you can keep going. Think of a straw with a little motor that does the sucking for you. Now it’s more of a drinking fountain. Nice and redundant.

Not in this case. The pump was not wired to anything – the wires that would provide it power dead-ended just a few inches away. Yet all fuel to the engine had to pass through this pump. It was old and kinda rusty.

It was no longer letting fuel pass through. I can’t remember exactly how I determined that – there’s a non-zero chance I pulled the hose between the pump and the Racor and sucked, and didn’t get any fuel in my mouth.

I was able to bypass the old fuel pump with parts on hand. I think I just cut the hose at the pump inlet and put it directly on the racor filter inlet – no new hose needed, just some fresh clamps. Or maybe I replaced the foot or so of hose here and used a coupler in place of the pump. I can’t remember. But after bypassing the dead pump, fuel could reach the priming bulb.

Then I just had to prime the Perkins. Honestly – you basically have to hug the hot engine, massage the fuel pump on one side while fiddling with bolts on the other. Nobody has a sense of humor like a mechanical engineer creating routine maintenance procedures like these. But I did it, and then Stephanie turned the key while I held the last bolt loose (at the highest injector) and watched for bubble-free fuel flow; it fired right up, and off we went towards Morro Bay. I was covered in sweat and diesel. I seem to wind up this way often.

I truly wish I had noticed this defunct fuel pump before we left the dock. And again, the astute observer might note that the cause and fix I just identified doesn’t match the symptoms! At least not exactly. We’ll talk about this in the second post. Yachting!

The whole process took about 2 hours from start to finish. I don’t remember being too concerned but I probably was – we weren’t in any danger, but also there was little wind in the forecast and we were about as far from safe harbor and spare parts or a mechanic as we would ever be on this route, and abreast of famously temperamental Point Conception. We watched a gorgeous sunset and Stephanie told me about all the whales I missed.

Everything worked fine to Morro Bay, where I bought a bunch more fuel hose in both sizes and hose clamps just in case, and indeed all was good the rest of the way to Alameda.

Wow! I learned so much. Super cool and very technical stuff!

Wow, I hope someday you will have the electric engine(s) of your dreams.